StarBright XLT Optical Coatings

StarBright XLT is Celestron’s revolutionary optical coating system that outperforms any other coating in the commercial telescope market. Our most popular Schmidt-Cassegrain telescopes come standard with this high-quality optical coating, making for an incredible value.

This article provides detailed information about how StarBright XLT is designed, and how StarBright XLT measures up against our previous StarBright coatings. We also provide information about our testing methods.

Celestron strives to design and engineer products with quality components using a state-of-the-art manufacturing process followed up with uncompromising quality assurance. You can see it in the design and quality of our entire product line, and StarBright XLT is no exception.

- Design: We design and test our optical coatings with the aid of thin film design software in wide use throughout the optical, semiconductor, aerospace, and telecommunications industries. Using this software, we have improved on our multi-layer enhanced mirror coatings, shifting the peak reflectance to the center of the visible spectrum. We have designed a completely new multi-layer anti-reflective coating and have introduced a new low-absorption, high-transmission glass for our corrector lens. This unequaled combination is standard with every StarBright XLT system.

- Quality components and process: Our coating process uses state-of-the-art thin film vacuum deposition technology. To ensure consistent optical coatings of the highest quality, the process is tightly monitored and controlled by highly-trained coating technicians. Prior to coating, each optical element is thoroughly cleaned and inspected to ensure proper adhesion of the films during the coating process. The materials used in our reflective and anti-reflective coatings are the purest available (exceeding 99.99%) and include aluminum (Al), hafnium oxide (HfO2), titanium dioxide (TiO2), silicon dioxide (SiO2), and magnesium fluoride (MgF2).

- Quality assurance: Our QA process prevents any optical element from passing if it does not meet our strict standards of optical quality. Witness plates are included in each coating run and are subjected to spectrophotometric analysis to determine if the minimum acceptable transmission or reflectance has been achieved.

StarBright XLT Products

-

NexStar 8SE Computerized Telescope

(2,038)Regular price $1,699.00Regular price -

NexStar 6SE Computerized Telescope

(126)Regular price $1,199.00Regular price -

NexStar 4SE Computerized Telescope

(1,140)Regular price $749.00Regular price -

NexStar 5SE Computerized Telescope

(1,135)Regular price $1,029.00Regular price -

NexStar Evolution 8 Telescope

(148)Regular price $2,399.00Regular price -

Omni XLT 150 Telescope

(48)Regular price $739.95Regular price -

NexStar Evolution 8 HD Telescope with StarSense

(9)Regular price $3,199.00Regular price -

NexStar Evolution 9.25 Telescope

(144)Regular price $2,999.00Regular price -

CPC Deluxe 1100 HD Computerized Telescope

(15)Regular price $5,499.00Regular price -

Advanced VX 8" Schmidt-Cassegrain Telescope

(26)Regular price $2,499.00Regular price

Optical Elements of the Schmidt-Cassegrain Telescope

A telescope is a group of optical elements that collects light and focuses it for observation through an eyepiece or similar imaging device. There are two types of optical elements: mirrors and lenses. Mirrors reflect light, while and lenses refract (bend) light. The Schmidt-Cassegrain telescope uses both mirrors and lenses, as seen in the cross-section diagram below. In this telescope, light passes through the corrector lens, reflects off the primary mirror, reflects off the secondary mirror, and finally comes to a focus at the focal plane.

Optical Coatings

The purpose of a telescope is to collect as much light as possible. The amount of light gathered affects the brightness of the resulting image. Unfortunately, there are sources of light loss at each optical surface and within each lens. Fortunately, the right optical coatings and lens materials can minimize the amount of light lost to these sources.

Optical coatings are very thin layers of material that are applied to the glass in a process called “vacuum deposition.” The physical properties and thickness of each layer in the coating, as well as their orientation with each other and the glass to which they are applied, determine how well they will do their job.

Since the function of a mirror is to collect light by way of reflection, we use highly-reflective metallic coatings on these optical elements. A mirror without coatings reflects about 4% of the light that hits its surface, but a mirror coated with standard aluminum coatings reflects about 86-88%—and a mirror coated with StarBright XLT reflects 95%.

Light traveling through a lens is a little more complicated, because light is lost to both reflection and absorption. When light first strikes an uncoated lens, about 4% is reflected back and never has the chance to make it through. Some of the remaining 96% will be absorbed on its way through the glass, and then the second lens surface reflects another 4%. To minimize unwanted reflection, dielectric materials are used in pairs of alternating high and low refractive index. A good anti-reflection (A/R) coating for telescope lenses is one that will deliver very low, very “flat” reflectance across the entire visible spectrum.

Although A/R coatings can dramatically reduce the amount of light lost to reflection, no optical coating can reduce the amount of light lost to absorption within the glass. To reduce this source of light loss, it is important to choose a glass that absorbs as little light as possible.

For many A/R coating applications, it is standard to measure the reflection of the coated surface and to ignore the amount of light that is being absorbed by the glass. But for a telescope lens, stating how well an A/R coating suppresses reflection without also revealing how much light is lost to absorption within the glass can be quite misleading. For this application, actual transmission—which accounts for light lost to both sources—should be measured directly. You can learn more about how we coordinated these measurements in “Our Measurements” section.

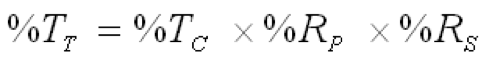

Telescope System Transmission

System transmission is the percentage of light that arrives at the focal plane compared to the light that enters the telescope. It is calculated by taking the product of the corrector lens transmission, the primary mirror reflectance, and the secondary mirror reflectance. Here is an example: if the corrector lens transmits 92% of the light, and the primary and secondary each reflect 89% of the light, then total system transmission is .92*.89*.89 = .73, or 73%.

StarBright XLT Optical System Design

One of the most important factors in the evaluation of a Schmidt-Cassegrain telescope’s optical system performance is its transmission, or the percentage of incoming light that reaches the focal plane. The design of the StarBright XLT system accomplishes a crucial objective: develop a coating system optimized for both visual use and for CCD/photographic imaging.

There are three major components that make up our StarBright XLT high-transmission optical system design:

- Unique enhanced multi-layer mirror coatings made from precise layers of aluminum, SiO2 (quartz), TiO2 (titanium dioxide), and Si02 (silicon dioxide). Reflectivity is fairly flat across the spectrum, optimizing it for both imaging and visual observing.

- Multi-layer anti-reflective coatings made from precise layers of MgF2 (magnesium fluoride) and HfO2 (hafnium dioxide). Hafnium—a rare element that costs nearly $1,500 per kilogram—gives us a wider band pass than the titanium used in competing coatings.

- High-transmission water white glass is used instead of soda lime glass for the corrector lens. Water white glass transmits about 90.5% without anti-reflective coatings; that’s 3.5% better transmission than uncoated soda lime glass. When water white glass is used in conjunction with StarBright XLT’s anti-reflective coatings, the average transmission reaches 97.4%: an 8% improvement.*

These three components of our StarBright XLT coatings result in one of the finest coatings available. The peak transmission for the systems is 89% at 520 nm. The overall system transmission is 83.5% averaged over the spectrum from 400 to 750 nm. The plot below shows the entire system transmission over the spectrum:

This plot is obtained by measuring the reflectivity of the secondary mirror and the primary mirror and measuring the amount of light transmitted through the coated corrector lens. Each of those values are multiplied together calculate the system transmission. The overall system transmission peaks at 88.9% while the average transmission is 83.5% over the spectrum from 400 to 750 nm.

StarBright XLT vs. Previous StarBright Coatings

StarBright XLT system transmission gives a 16% improvement compared to the previous StarBright coatings. The average system transmission for StarBright coatings is 72%, while the average system transmission for StarBright XLT is 83.5%. StarBright uses soda lime glass correctors, whereas StarBright XLT uses water white glass, which improves the corrector throughput dramatically.

StarBright XLT is a 16% improvement over StarBright,* with the peak transmissions being 89% and 80% respectively.

StarBright Mirror Reflectivity Comparison

StarBright XLT mirror reflectivity peaks at 95% and has an average reflectance across the spectrum of 93%. The previous StarBright peaks at 94% with an average reflection of 91% across the spectrum.

StarBright Corrector Transmission Comparison

StarBright XLT’s corrector transmission is 97.4% versus StarBright with 87% and UHTC with 91% across the spectrum from 450 to 750 nm.

StarBright XLT is a 12% improvement over StarBright transmission.* StarBright XLT has peak transmission at 99%, while StarBright peaks at 91%.

*Percent differences are calculated by taking the comparison data percentage divided by the baseline data. Example: measured average system transmission for current StarBright is 72%. StarBright XLT average system transmission is 83.5%. 83.5% divided by 72% = 1.16 or 16% improvement. Measurement results are rounded to the nearest whole percentage.

Testing Methods

Total telescope light throughput can be measured in two different ways: measurement of the assembled optical system, or measurement of the reflectance of each mirror (or reflective element) and the transmission of each refractive element in the optical path. In the case of a Schmidt-Cassegrain telescope, there are two reflective elements—the primary and secondary mirrors—and one refractive element, the Schmidt Corrector. See diagram below:

Analysis of Assembled Telescope vs. Individual Optical Elements

To measure the throughput of the assembled telescope, a beam of light is passed through the telescope and compared to a beam of equal intensity light passing through air only. Total telescope throughput is the ratio of light intensity measured through the telescope divided by the light intensity measured through air. This is easily said, but very challenging to execute correctly. Great care must be taken to ensure that the reference beam is of constant intensity, and that its light is collected in a manner which does not bias the results. Errors introduced by beam geometry (f ratio) at the entrance to the detector and less-than-perfect alignment of the optical elements, including placement and dimensions of internal light baffles, will tend to reduce the intensity of light measured through the telescope.

The second method of measuring total telescope throughput—spectrophotometric analysis of each element in the optical path—is not susceptible to these sources of error. Furthermore, individual element analysis provides specific information about each optical element, while measuring the throughput of the assembled optical tube does not. Results obtained in this manner represent an upper limit to the actual throughput of the assembled telescope.

Total telescope throughput (%TT) is equal to or lesser than corrector plate transmission (%TC) times primary mirror reflectance (%RP) times secondary mirror reflectance (%RS)

Corrector Plate Transmission (%TC)

We use a Shimadzu UV1601 spectrophotometer for analysis of corrector plate transmission. This is a double beam instrument with a spectral range of 190 to 1100 nm. Transmission data is typically collected in the visible region from 400 to 750 nm. Small samples of corrector material called witness plates are included in each corrector coating run. In order to minimize handling and the possibility of scratching a full-size corrector plate, we use these witness plates to represent the transmission characteristics of our correctors.

Our instrument is capable of measuring the transmission of correctors up to 8” diameter. If this is necessary, the corrector plate is measured at four points roughly 90° apart, and the results are averaged. Before and after each measurement, baseline (100%) measurements are made to ensure light source and/or detector drift is negligible.

Primary and Secondary Reflectance (%RP, %RS):

The preferred method of measuring reflectance of primary and secondary mirrors also involves the use of witness plates. These are small (1” to 2” diameter) flat polished glass substrates, which are coated along with the primary and secondary mirrors. Since the coating process is the same, and the surfaces are equally well polished, the reflectance of the witness plate is the same as that for the primary and secondary mirror. The reasons for using flat witness plates are 1) the primary and secondary mirrors are not themselves subjected to a measurement process which can potentially cause scratches, and 2) very simple test methods and readily available reference standards can be used to measure the reflectance of flat surfaces.

Typically, the reflectance of a surface is measured against a standard reference of known reflectance. Our standard reference is an enhanced aluminum-coated quartz flat, calibrated against a NIST (National Institute of Standards and Technology) specular reflectance standard. To measure the reflectance of a flat sample, the baseline measurement is made using this standard, and the reflectance of the sample is compared to this baseline.

Sample reflectance factor (%RS) is equal to its reflectance relative to the reference standard (%RSR) times the reference standard’s known reflectance (%RR)

However, if the sample to be measured has a curved surface like a secondary or a primary mirror, and there is no witness plate available, then special care must be taken to ensure that the method used to measure reflectance is insensitive to this curvature. If we compared the reflectance of a curved surface directly to that of a flat reflectance standard, our results would not be accurate, since the converging or diverging beam generated by a curved surface would direct either less light (in the case of a secondary mirror), or more light (in the case of a primary mirror) onto the detector than was directed by the flat reference standard.

The most widely-used tool for measuring the reflectance of curved surfaces is called an integrating sphere. This device collects and then measures the intensity of light in a manner which is insensitive to beam geometry, hence, insensitive to surface curvature of a reflective sample being measured. However, integrating spheres can be quite expensive and are time-consuming to set up and calibrate. We developed a method which is equally insensitive to surface curvature, but much less costly and time consuming to perform. We made our own reference standards from secondary and primary mirrors with the same surface curvature as those we wished to test.

We obtained samples of the secondary and primary mirrors which we wished to test, stripped the existing coating, and replaced it with one for which we also obtained flat witness plates. These flat witness plates were calibrated against a NIST specular reflectance standard. Since the flat witness plates were coated along with the curved samples, and since we have adequate data to show that our coatings are very uniform from part to part in any given coating run, we can apply this reflectance data to our curved samples. Using these curved surface reflectance standards we are able to measure other mirrors of the same curvature just as we use our flat reflectance standard to measure the reflectance of flat samples.

To perform these measurements, we use an Ocean Optics USB2000 Spectrometer with an LS-1 Tungsten Halogen Light Source. This is a single-beam instrument with a 0.3 nm resolution, a scanning range from 340nm to 1024nm, and is equipped with a fiber-optic curved surface reflectance measuring probe.

Reporting the Data:

Collecting the data and reducing it to yield total telescope throughput (%TT) (system transmission) is simply a matter of multiplication. We find the average of each data set (%TC, %RP, and %RS) for each wavelength measured, and multiply them together.